|

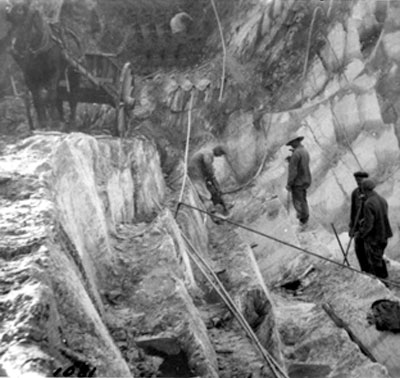

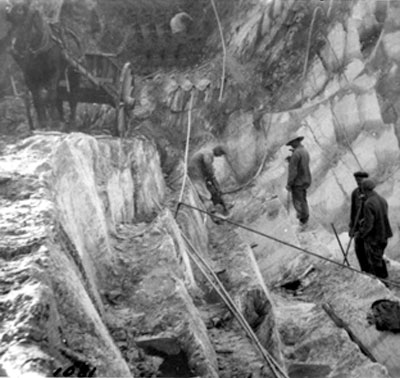

A photo of the Broughton mine in 1927: this photo exemplifies

the quarrying techniques used in this mine at the time. |

|

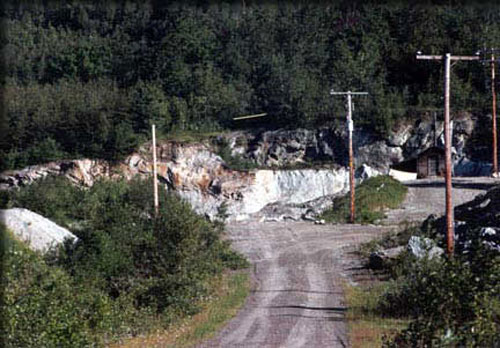

In an older section of the mine, you can see how the blocks

of soapstone were cut.

Each block having to be cut a foot from the previous block gives

the wall a stair like effect. |

|

|

In 1933 the Cyr family constructed an office building for

the company using blocks and lintels of soapstone. The township

has been given the building by the previous owners and intend

to convert the building into a soapstone museum. |

|

|

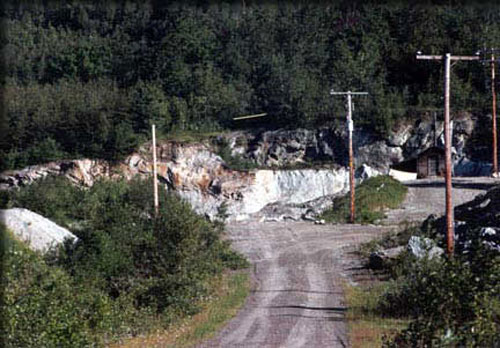

This is the view of the original pit that I visited when I

first started buying my stone from them in 1971.

Between 1925 and 1927, a massive steatite horizon was quarried

northwest of Saint-Pierre-de-Broughton to produce refractory

blocks and pencils to make marks on glass or steel. The quarry

is located at the northwestern end of the Pennington sheet At

this place, the original serpentinite is almost completely transformed

into steatite and talc-carbonate rock

Stone was mined from this quary from 1927 until 2002, when

they announced that the quarry was to be closed for good, |

|

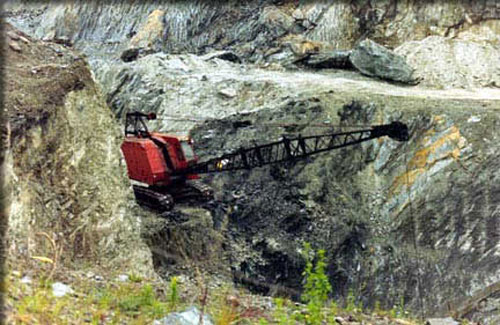

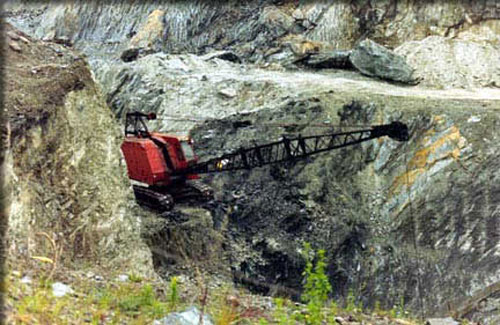

The mine has been quarrying soapstone in different locations

for various purposes (powdered talc used, among other things,

for asphalt products dusting, joint cement and insecticide dust)

since the 1880"s.

The stone is also used as soapstone slabs in the construction

of wood stoves.

From this long period of use, the quarry had become so deep that

a crane was used to raise the blocks from the depths of the quarry. |

|

|

The stone was cut from the wall of the quarry , by drilling

a line of holes into the next layer of stone.

The block is then separated along the grain of the stone and

raised to the surface by the crane.

The old pit became to deep and troublesome to operate.

With the new pit in operation, the abandoned old quarry has filled

with water. A 300 foot deep swimming hole. |

|

|

|

When I first came to the mine in the early 70's, the stone

was cut using six foot circular saws. In the 1990's the company

had progressed to using a bandsaw. |

|

|

|

|

These blocks would be cut into thesizes that

customers ordered. |

|

|

In the storeroom the cut blocks of soapstone are stacked

and waiting for a sculptor to turn it into his personal work

of art. |

|

The old quary - 2006 |

The new quarry - 2008

The new quarry - 2008 |

|

Les Pierres Stéatites Inc is the only commercial

talc mine I know that mine soapstone specificly for sculpture.

These pictures where taken about ten years ago

showing the removal of the blocks of soapstone in the new quarry

at that time. |

|

|

The stone was cut from the floor of the quarry , by

drilling a line around the desired block of stone.

The block will then be separated along the grain of the stone.

Here you can see them removing the soapstone block by

block. |

|

|

One of these blocks will weigh about four tons. |

|

Here are shown some of the tools that were used in

separating the stone from the floor of the quarry.

By cutting the stone from the floor by hand, the

mine can supply quality, fracture free blocks of soapstone for

carving |

|

|

|

|

|

With the new cutting techniques, this what the quarry

looks like today. |

|

This is the site of Pierre de Stéatite cutting

operations.

770, rang 7 Nord, East Broughton, Quebec, GON 1H0 |

|

|

|

|

|

|

|

|

|

|

|

Here are a few maps to help

you get to the quarry |

|

New York to Pierres

Stéatites Inc |

Boston to Pierres Stéatites

Inc |

|

Atlanta to Pierres

Stéatites Inc |

Buffalo to Pierres

Stéatites Inc |

|

Detroit to Pierres

Stéatites Inc |

Toronto to Pierres

Stéatites Inc |

|

General area to Pierres Stéatites

Inc in East Broughton |

East Broughton, Quebec |

|

|

|

|

|

|